The Process

Get wood, cut wood, glue wood, sand wood, oil wood. Voila.

1. Start with the sides

The Process

The sides are cut to roughly 1.8mm, endmatched, tapered along the lower edge, and soaked in hot water for an hour while the bending iron heats up.

2. Bending iron

The Process

This is an old soldering iron, with an offcut of galvanised water pipe added to increase diameter. It takes a minute or two to bend each side.

3. Side jig

The Process

Clamp it in the jig and leave it to dry.

4. 1+1=1

The Process

Trim the sides to length, and bring the two together, gluing in the neck and tail blocks.

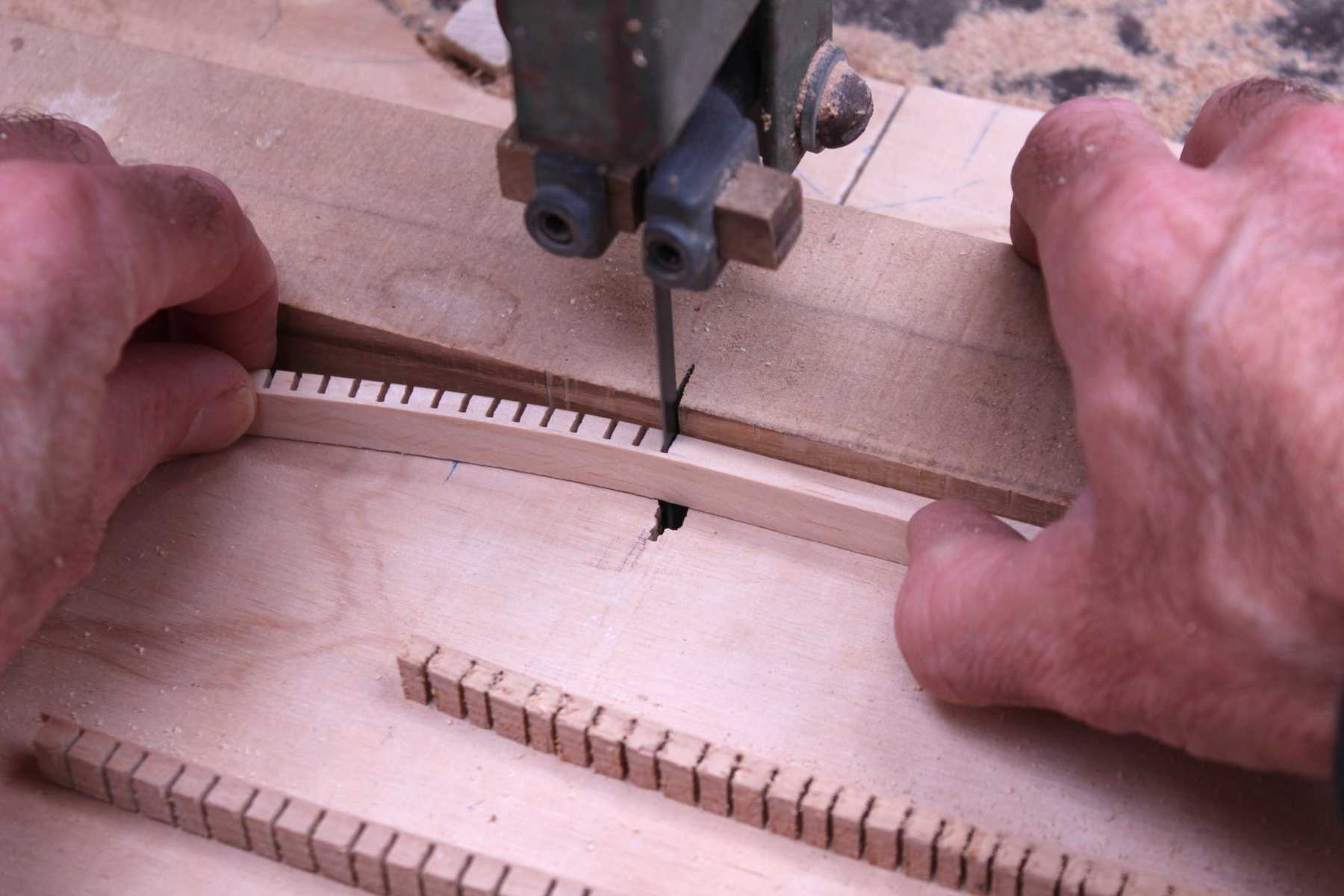

5. Kerfing

The Process

The bandsaw with a simple depth stop makes a very effective kerfing cutter.

6. Gluing the kerfing

The Process

The kerfing can be shaped to suit, and held in place with pegs whilst gluing with Titebond.

7. Cutting tops and backs

The Process

All tops and backs are bookmatched to emphasise the grain patterns and features in the wood.

8. Joining

The Process

A simple jig to clamp the two-piece tops and backs.

9. Ready for thicknessing

The Process

Accurately controlling the thickness of the top is essential to get a good sound.

10. Thicknessed

The Process

Depending on the instrument, and the soundboard wood itself, the ideal thickness will vary a little.

11. Shaving the braces

The Process

The secret to a good sound is the type and shape of bracing. Shaving the braces down until the flex is just right. Too stiff and the ukulele will sound like all those factory made ones. Too flexible and you'll be sending the ukulele back for a new soundboard.

12. Back braces

The Process

These are curved, which along with the gently tapered sides, results in a slightly domed back - both aesthetically pleasing and stronger.

13. Assembling the body

The Process

These soft-jawed irwin clamps are perfect for the job.

14. Neck blank

The Process

Roughly cut out on the bandsaw

15. Fretboard

The Process

This hunk of Puriri looks a bit gnarly on the outside, but it's the perfect colour, density and workability for fretboards.

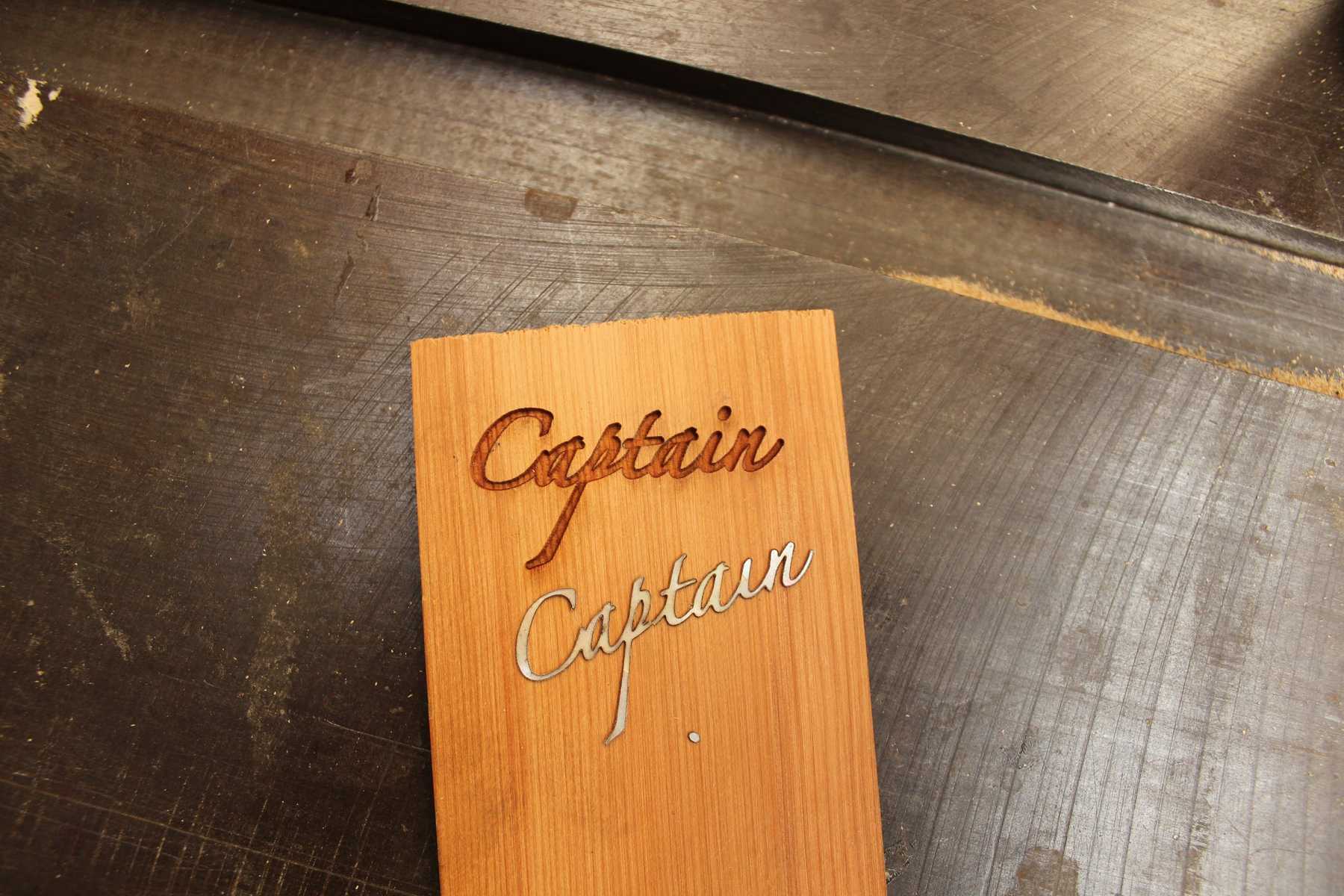

16. Engraving

The Process

The one part of the process that doesn't take part in the workshop. The rastering is done in town at Davy's Engravers.

17. Neck assembled

The Process

...and ready for shaping

18. Shaping

The Process

The trusty belt sander is a very useful tool for many things, and shaping necks is one of them. Start on 40g and end up on 120g, then it's off to the finishing sander.

19. Shaped

The Process

...and ready for a whole lot more sanding.

20. Cutting fret slots

The Process

No mitre box in this workshop! Just a good fretsaw and careful sawing.

21. Fretting

The Process

An old panel beating hammer with a wood face to gently bash the frets in.

22. Ready for dressing

The Process

Checking for level frets, and then each fret is dressed on the ends so it'll be nice to play.

23. Assembly

The Process

Titebond is used for all gluing. It's the 'original' red bottle, and is great to work with.

24. Nut slotting

The Process

The nut and saddle are made from corian. Using proprietary nut files is recommended, in order to get them perfect. Otherwise buzzing will result.

25. The workshop

The Process

Here is where it all happens. And if you think it looks like that now, you'd be mistaken. I haven't seen that floor in many years.